Founded in 2009,Dongguan Shenhua Mechanical and Electrical Equipment Co., Ltd is is a high-tech enterprise specializing in intelligent

precision cleaning and cleaning equipment. The company is composed

of more than 20 professional technicians. It has established

equipment development, production, sales and service. The main

modern enterprise system is one of the domestic professional

cleaning equipment, cleaning equipment technology research and

development and operation team.

In China, we have established

Dongguan Shenhua Electromechanical Equipment Co., Ltd.,

Dongguan Shenhua Electromechanical Equipment Production Factory,

Suzhou Shenhua Electromechanical Office

Xian Shenhua Electromechanical Office

Chongqing Shenhua Electromechanical Office.

Hong Kong Shenhua Electromechanical Equipment Co., Ltd.

With high quality products and strong technical strength, we

have become a good equipment supplier for many world famous

factories. Overseas, we have established a comprehensive sales

channel in the United States, Japan, Singapore, Malaysia, Brazil

and other markets through a number of agents.

SME staff insist on research and develop high

quality and smart cleaning equipments for electronic industry.

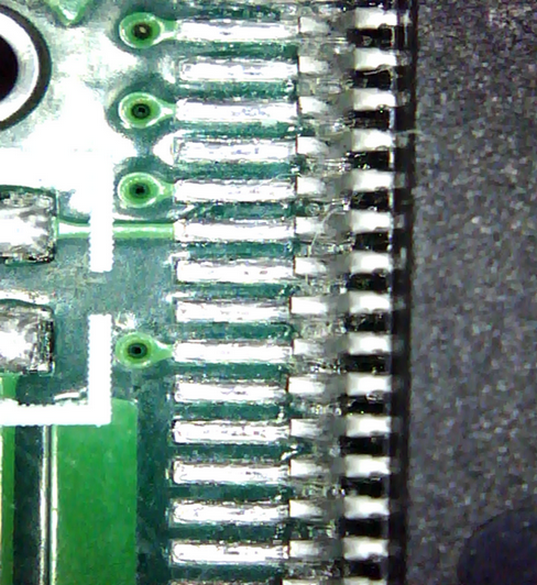

In SMT cleaning feild: we have installed stencil

cleaning machines, nozzle cleaning machines, misprinted PCB

cleaning machines,

squeegee cleaning machines and solder wave oven fixture

cleaning, reflow oven cooler cleaning machines, PCBA offline

cleaning machines

and PCBA in line cleaning machine, PCB inline cleaning machine.

In screen cleaning feild: we have installed Screen cleaning

machine, screen developping and stripping machine, ink

squeegee cleaning

machine.

In semiconductor field: we have BGA water cleaing

machine, IPM,SIP, FC,PLP,WLP, 3D package cleaning

machine, Cassette ultrasoinc cleaning machine,widely used in SMT,

PCB, TP, Semiconductor, solar, photovoltaic and other industires.

With the tenet of “Quality, professionalism, innovation and

service”, SME aims to develop and expand intelligent precision

cleaning and

cleaning equipment. We look forward to cooperating with you for a

better tomorrow.